From Sprockets to Idlers: The Total Solution for Trustworthy Undercarriage Parts

From Sprockets to Idlers: The Total Solution for Trustworthy Undercarriage Parts

Blog Article

Essential Overview to Undercarriage Parts for Heavy Equipment

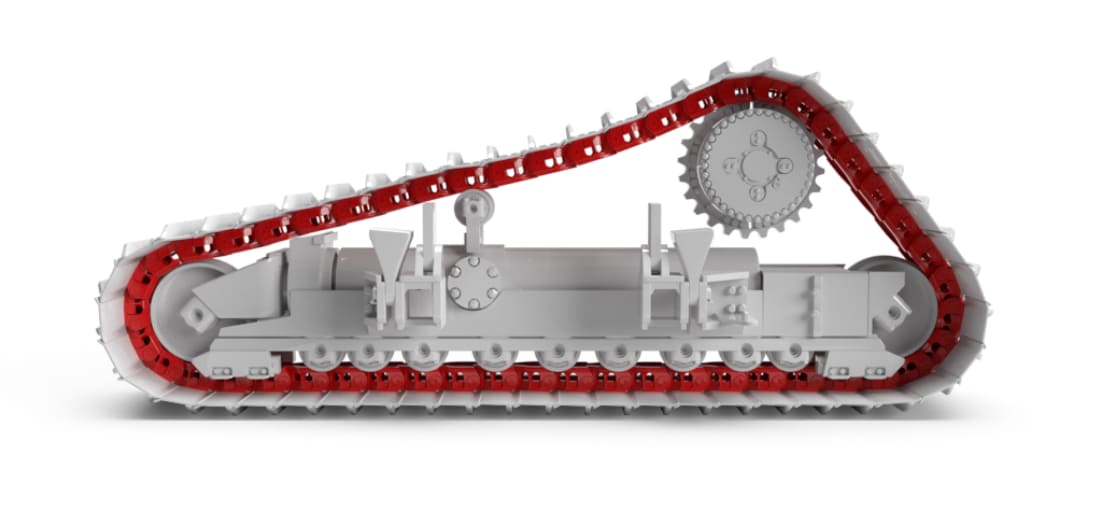

When it comes to heavy devices, the undercarriage plays an essential duty in guaranteeing efficient and smooth operations. From track chains to rollers and idlers, each part contributes to the overall capability of the tools.

Relevance of Undercarriage Components

Understanding the crucial role that undercarriage components play in the performance and longevity of heavy tools is vital for reliable maintenance and procedure - undercarriage parts. The undercarriage components form the foundation on which the entire equipment operates, sustaining the weight of the equipment, giving stability, and taking in shock loads during operation. A well-maintained undercarriage not just makes certain smooth operation yet likewise adds substantially to decreasing downtime and repair work costs

The undercarriage includes various vital parts such as track chains, track shoes, gears, idlers, rollers, and track frames. Each of these elements plays an important role in the total performance of the tools. The track chains and track footwear help in supplying traction and support, while the idlers and gears help in driving the tracks smoothly. Normal evaluation, prompt maintenance, and substitute of worn-out undercarriage parts are vital to avoid break downs and make the most of the life expectancy of the heavy tools. Fundamentally, spending in top quality undercarriage components and ensuring their proper treatment is vital for optimum performance and sturdiness of hefty equipment.

Kinds of Track Chains

Track chains are essential elements of hefty tools undercarriages, offering the necessary traction and support for efficient procedure. There are mainly 2 sorts of track chains utilized in heavy devices: sealed and oiled track chains (SALT) and completely dry track chains. Sealed and oiled track chains are commonly located in modern-day heavy machinery. These chains are pre-lubricated and secured to stop dust, particles, and dampness from going into the chain joints, ensuring smooth operation and expanding the chain's life expectancy. On the other hand, completely dry track chains require routine hands-on lubrication to preserve ideal performance and stop early wear.

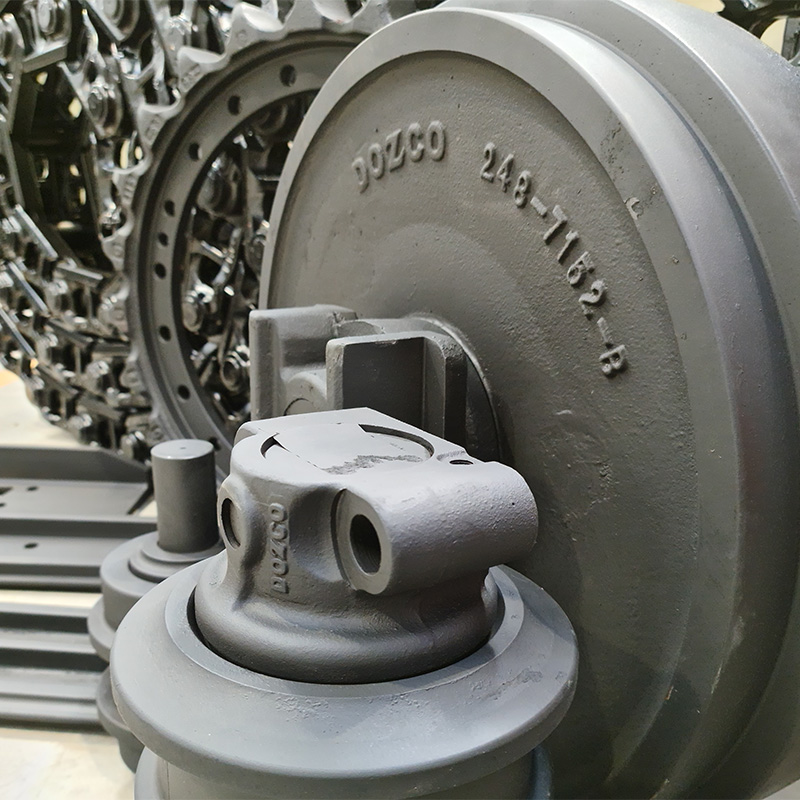

Role of Rollers and Idlers

Rollers and idlers play an essential duty in sustaining and directing the track chains of hefty tools undercarriages, adding to the general stability and effectiveness of the equipment. Rollers are designed to support the weight of the devices and provide a smooth surface area for the track chain to relocate along. They aid disperse the weight uniformly, minimizing too much wear on the track chain and making sure appropriate traction. Idlers, on the other hand, overview the track chain and help keep proper stress home throughout the undercarriage system. By guiding the track chain in a controlled manner, idlers prevent excessive side-to-side activity, reducing the risk of derailment and uneven wear.

With each other, rollers and idlers operate in consistency to make sure that the track chain stays in place, also on harsh terrain, enhancing the equipment's performance and durability. Correct upkeep and routine evaluation of rollers and idlers are vital to protect against early wear and possible break downs, ultimately taking full advantage of the performance and lifespan of hefty devices undercarriages.

Recognizing Gears

One critical facet of gears is ensuring proper placement and tension to avoid early wear and damage. Misaligned sprockets can trigger unequal endure the track chain, bring about reduced performance and possible safety hazards. Normal upkeep and evaluation of gears are important to recognize any indications of wear or misalignment promptly.

Furthermore, sprockets come in numerous dimensions and tooth configurations, relying on the particular heavy devices and its designated use. Proper option of gears based upon the equipment's requirements is essential to make certain optimum efficiency and durability of the undercarriage system. Comprehending the duty of sprockets and their maintenance requirements is essential for taking full advantage of the performance More Bonuses and life-span of heavy equipment undercarriages.

Upkeep Tips for Longevity

To make certain the long term resilience and optimum functionality of heavy devices undercarriages, persistent maintenance practices are vital. Routinely checking undercarriage components such as track footwear, rollers, idlers, and gears for wear and tear is critical. Correct track tension modification is likewise crucial for minimizing premature wear on undercarriage parts.

Conclusion

In final thought, undercarriage components are crucial elements for heavy equipment, playing crucial functions in keeping security and performance. Appropriate care and interest to undercarriage components are crucial to optimizing equipment lifespan and efficiency.

The undercarriage consists of different crucial parts such as track chains, track footwear, gears, idlers, rollers, and track structures. The track chains and track shoes aid in offering traction and assistance, while the gears and idlers assist in driving the tracks smoothly (undercarriage parts). There are mainly two types of track chains utilized in heavy tools: sealed and oiled track chains (SALT) and dry track chains. Proper choice and upkeep of track chains are essential to ensure the general check that efficiency and long life of heavy tools undercarriages

Sprockets are important parts of heavy devices undercarriages, accountable for moving power from the machinery to the track chain.

Report this page